Table of contents

What is the Kraljic model?

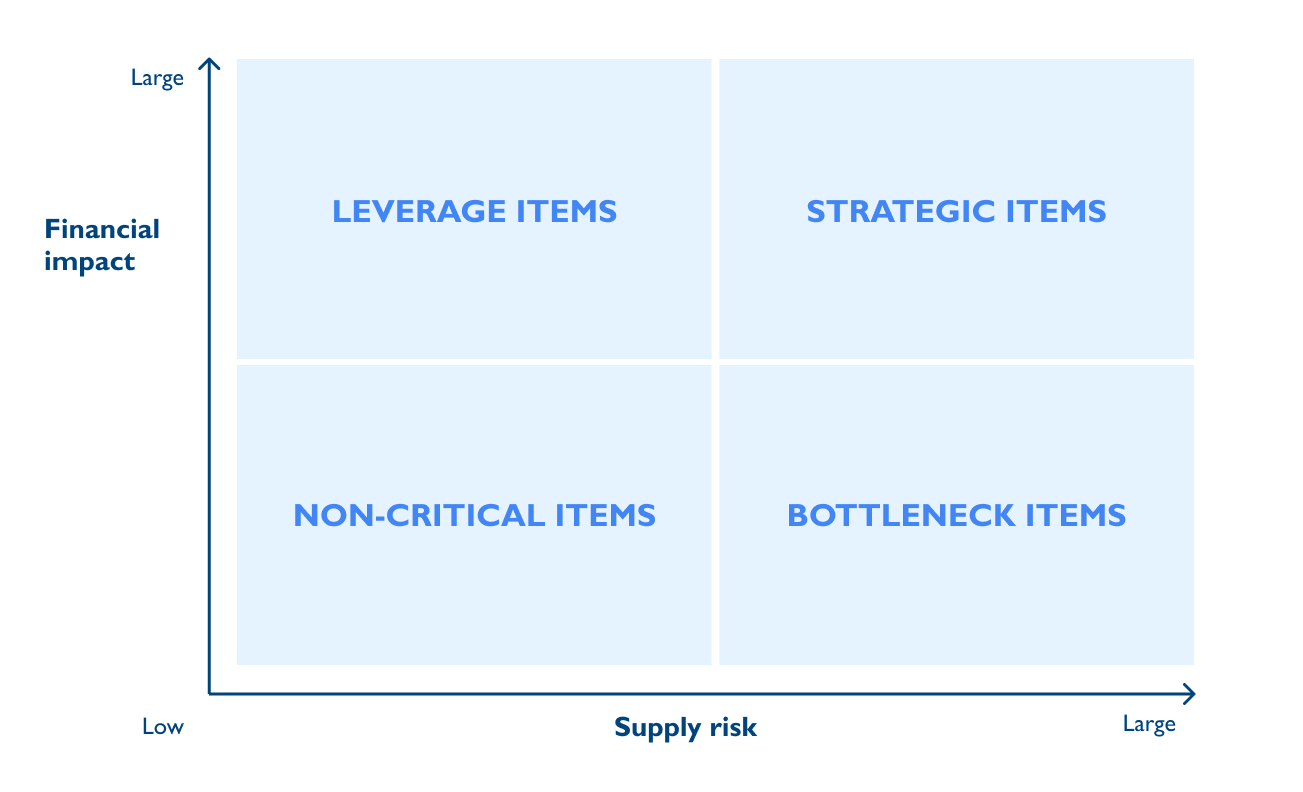

The Kraljic Model, developed by Peter Kraljic, is a well-known 1983 procurement model. It provides a structured approach to optimize purchasing strategies by categorizing items based on business impact and supplier dependency. Categories include strategic products, bottleneck products, leveraged products and routine products. The Kraljic model has become a standard since the 1980s and is used worldwide. When you apply this model, it can lead to optimized procurement processes, long-term relationships and growth and profitability of your organization.

Routine products

When purchasing routine products, emphasis should be placed on minimizing administrative effort by using framework contracts. These are typically characterized by low cost, high availability and low risk of failure.

Leverage products

Leverage products are high value items with low complexity and sufficient suppliers. These should put energy into contract negotiations on pricing and value-added. Standard contracts and tender conditions usually suffice, with limited contract duration.

Bottleneck Products

The products have a low value, but can only be sourced from one or a few suppliers. This often leads to higher prices, long delivery times and poor service. A concern in contracts for these products is ensuring delivery is the main priority.

Strategic products

High-value products are usually supplied by one or a few suppliers. Most products require close monitoring of price trends, targeted pricing, a focus on negotiation and building trust. Moreover, they are often customized to meet consumer demands.

The history of the Kraljic model

The Kraljic model was developed in 1983 by Peter Kraljic, a German procurement expert. It is used to help purchasing managers differentiate items according to their impact on operations and degree of dependence on available suppliers.

It groups them into four categories: strategic, bottleneck, leverage and routine. The model has become a standard tool worldwide and is used to optimize procurement processes and increase the profitability of organizations. Even with technological advances and changing economic conditions, it remains an important tool for those seeking to establish efficient and effective procurement processes.

FREE WHITE PAPER

Reduce Total Cost of Ownership (TCO) with the Kraljic Matrix

The purpose of the Kraljic model

The Kraljic matrix is a procurement management tool designed to help companies optimize their policies. It helps them determine the right strategies for different types of products and services based on their complexity and importance. This model helps you reduce costs while increasing low value. Reduce the amount of time and money spent per product with the correct application of the model.

We will explain how it works and how to implement it effectively. Whether you’re a buyer looking to improve efficiency or a business leader looking to cut costs, this blog offers insights and tips on optimizing procurement activities with the Kraljic model.

The components of the Kraljic model: the axis of financial risk and the axis of subcontracting

The Kraljic matrix categorizes procurement items based on their impact on operations and degree of supplier dependence. It divides them into four categories: strategic products, bottleneck products, leveraged products and routine products.

Strategic products are essential with high impact, while bottleneck products are both important and uncertain.

Leverage products have low impact with potential for cost optimization and routine products have low impact but can be easily sourced. This model can provide structure to your procurement management processes while reducing your risks.

What is the process of the Kraljic model?

The Kraljic model process involves categorizing products according to their importance and dependence on the number of suppliers. Two axes are used: the financial risk axis to assess the operational impact and the supply chain axis for the amount of supplier dependence.

This creates four categories: strategic, bottleneck, leverage and routine. This allows organizations to identify which components need special attention or cost optimization, require early supplier involvement and which products are simple. By applying the Kraljic model, a strategy can be developed for each product based on their category.

Free whitepaper

Project Procurement in the Machine Building Sector

In what industries can the Kraljic model be used?

The Kraljic model is a widely used procurement model in various industries, such as industrial, construction and retail. It can help optimize the procurement of raw materials, machine parts and semi-finished goods in the manufacturing sector, building materials in the construction sector and goods for retail sale. In addition, the model can be applied in the service industry for medical device management or other similar matters.

This tool leads to a structured approach to procurement management, which in the long run ensures cost savings and risk minimization. Applying the Kraljic model is very useful because it can help your organization optimize procurement processes while achieving greater growth and profitability.

Case studies of companies that have successfully implemented the Kraljic model

The Kraljic model is a very useful model and is successfully used by many companies and helps in optimizing procurement. Some examples of its application are at American computer company Dell and Dutch supermarket chain Albert Heijn. Dell was able to reduce costs, follow technological development and improve product quality, while Albert Heijn represented the products and improved product quality, leading to a better return on investment.

It turns out that the Kraljic model can help companies regardless of industry or purchasing requirements. Successful implementation and optimization requires an investment of resources and expertise. The importance of procurement should not be underestimated, as it directly has a major impact on the financial bottom line.

Find a buyer through xentys

At xentys, your experienced procurement recruitment agency, we are happy to help you find the right professional for your procurement team. Send a message today and strengthen your purchasing department.

Tips for using the Kraljic model in your own business

To use the Kraljic model successfully, the following tips can be used:

- Assess the importance of each product: It is important to start by assessing the importance of each product in your company’s supply chain. Make sure this assessment includes factors such as cost, risk and dependence on the number of providers.

- Divide the products into four categories: Once the importance of each product has been assessed, it can be classified into one of four categories: strategic, bottleneck, leverage and routine.

- Develop an appropriate strategy for each product: Once categorization is successful, develop an appropriate strategy for each product based on the category. For example, certain agreements can be made with suppliers. Strategic products may require more attention and resources than routine products, while higher volume bottleneck products require external help.

- Monitor performance regularly: Finally, it is important to regularly monitor the performance of your procurement processes to ensure they remain efficient and cost-effective. Adjust your strategies as necessary to optimize performance over time.

Conclusion

The Kraljic model is a valuable procurement model that helps companies maximize their procurement procedures. It categorizes procurements based on financial impact and uncertainty, allowing companies to tailor their strategies to the specific market and business needs. This structured approach can reduce costs and risks and requires ongoing assessment of procurement methods in view of changing markets.

Companies that have regularly applied the Kraljic model save costs, increase quality and improve profitability. That being said, it is important that companies implement this model effectively and devote sufficient resources to optimize procurement processes.